dayton form savers 3d drawing

Autodesk's Fusion 360 is a versatile CAD package that has all the features needed to develop products from the conceptual phase through blueprint verification to manufacturing on both traditional and digital fabrication tools like 3D printing.

In this article, yous'll find a quick overview of Fusion 360's interface and features for 3D printing as well as detailed tips to help you gear up parts for 3D press.

Fusion 360 is a cloud-based CAD platform that is an affordable, highly capable alternative to other major players in the industry. It is easy to employ and has all the common features you can expect from popular CAD packages. Fusion 360 was built from the ground up to be an all-encompassing production development solution and aims to offer a simple workflow from conceptual design all the way through manufacturing.

Fusion 360 has a very big cognition base of operations that thoroughly covers every characteristic of the software, these tutorials tin can be accessed through Fusion 360 every bit well as through the Autodesk website. At that place is also an official YouTube aqueduct with many hours of free tutorials.

The software receives frequent upgrades and new features arrive every few months. Fusion 360 is platonic for loftier turnover businesses besides as beginning-ups looking for a professional tool to get them into the marketplace.

Fusion 360 can perform resource-intensive operations on the deject, including rendering, simulation, shape optimization, and generative blueprint. This means that work tin can keep while all the heavy lifting is done on the cloud.

There are diverse licensing packages bachelor, these are listed below:

- Complimentary Trial: Autodesk offers a thirty-day free trial upon signup.

- Educational: Like most other CAD packages, Fusion 360 comes with an educational license to students, educators, and bookish institutions.

- Commencement-up: A gratis license is bachelor for kickoff-ups, enthusiast, and hobbyist. In order to use this license, the user must run a company that has a turnover of less than $100 000 per yr. The showtime-up license does not include any of the more advanced features such every bit generative design.

- Commercial: In that location used to be two versions of the paid license, namely a standard and ultimate, just these take been merged into ane version that contains all the features that used to exist in the ultimate version. The fees are structured equally a subscription model.

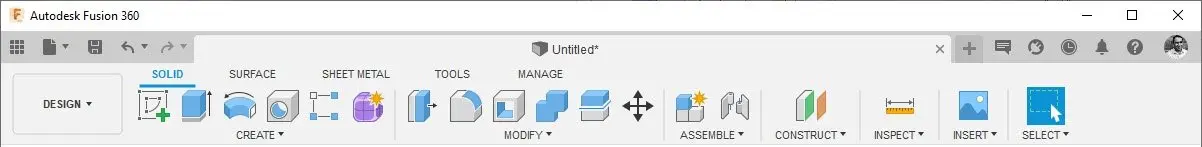

In Fusion 360, yous tin switch between 7 dissimilar workspaces. Each workspace has its ain set of tools and functions:

- Design: For drawing 3D models and surfaces by making use of sketches, extrusions, revolves, and many other standard CAD tools.

- Generative Design:Generative Blueprint is a class of artificial intelligence that leverages the ability of the deject and machine learning to output efficient design iterations based on your mechanical constraints.

- Return: Create photorealistic renderings of components and products.

- Animation: Animate assemblies to see if they function as expected or to show functionality to prospective clients.

- Simulation: Computer-aided engineering to perform various stress analyses on the designs to make sure they can handle the operating atmospheric condition.

- Manufacture: Figurer-aided manufacturing (CAM) to help with manufacturing the part on various digital fabrication tools, such as CNC mills, CNC lathes, light amplification by stimulated emission of radiation cutters, and waterjet cutters.

- Cartoon: Create shop drawings of designs for manufacturing in a traditional manual auto shop or to back-trail the K-code for CNC machined parts.

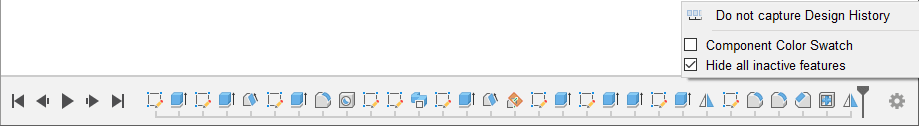

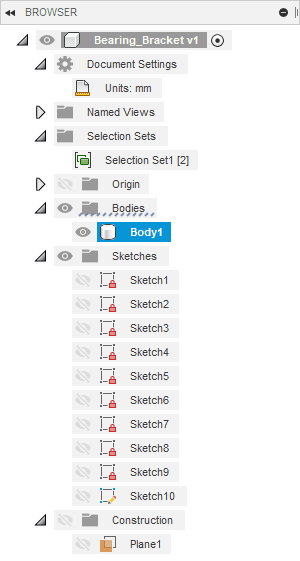

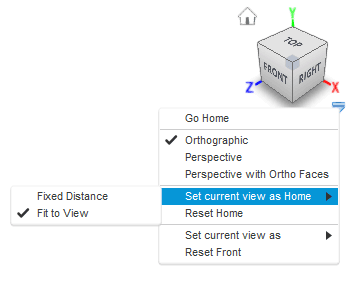

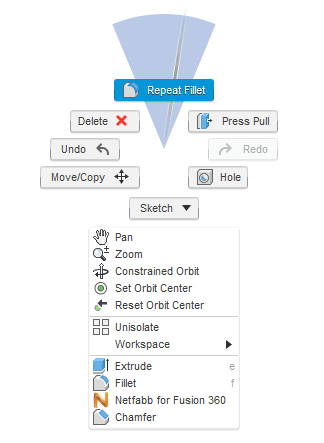

The Fusion 360 workspace is divided into vii principal sections, namely the tool bar, data console, navigation, timeline, browser, view cube, and the marking menu. Each of these is described in more than particular below.

The toolbar contains all the tools and features that are available in a workspace. In the instance of the design workspace, these tools assist create and alter 3D models, surfaces, sheet metal, and assemblies.

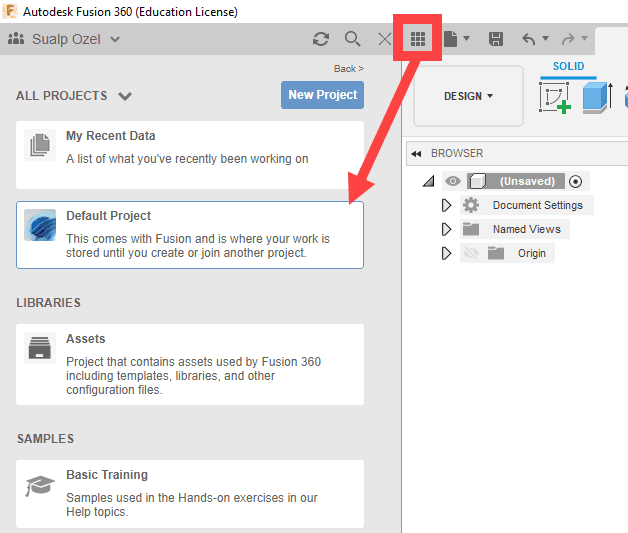

The information panel allows the user to open existing projects, create new ones, manually save a project and access the data console. The data console is a space where designs tin can be saved and organized in an piece of cake to navigate format. The data console allows y'all to create projection folders too every bit a place to notice sample parts and tutorials.

The navigation bar contains all the tools for rotating, translating and changing the visual style of a model. There are also options to break the canvas into subsections with each indicating a different view of the model.

The timeline shows a history of all the operations performed to create the part. This includes all features, patterns, material changes, and sketches to name a few. This is a unique feature that allows yous to see the complete history of their part without having to navigate through the browser tree. Whatever feature can be modified with a right-click within the timeline. The timeline tin also be used to detect that specific feature in the browser tree.

The browser contains all the components, features, bodies, sketches, and construction geometry of a design. The browser takes the form a tree-like structure which should be familiar from common CAD packages.

The view cube allows you to manipulate the model in a more structured style. By clicking either on the corners, edges, or faces of the cube the model will re-oriented inside the sail. This makes information technology easy to switch between standard views. If the user clicks the arrow on the bottom correct of the view cube, a drop-downwards menu appears that provides more than options to command the view.

The marking carte du jour is a situation specific pop-up menu that contains commonly used features, information technology tin can exist accessed by clicking correct on the model or the canvas. The features that bear witness up in the carte du jour are determined by what is clicked and what workspace is currently active. This carte du jour helps increase modeling speed and convenience.

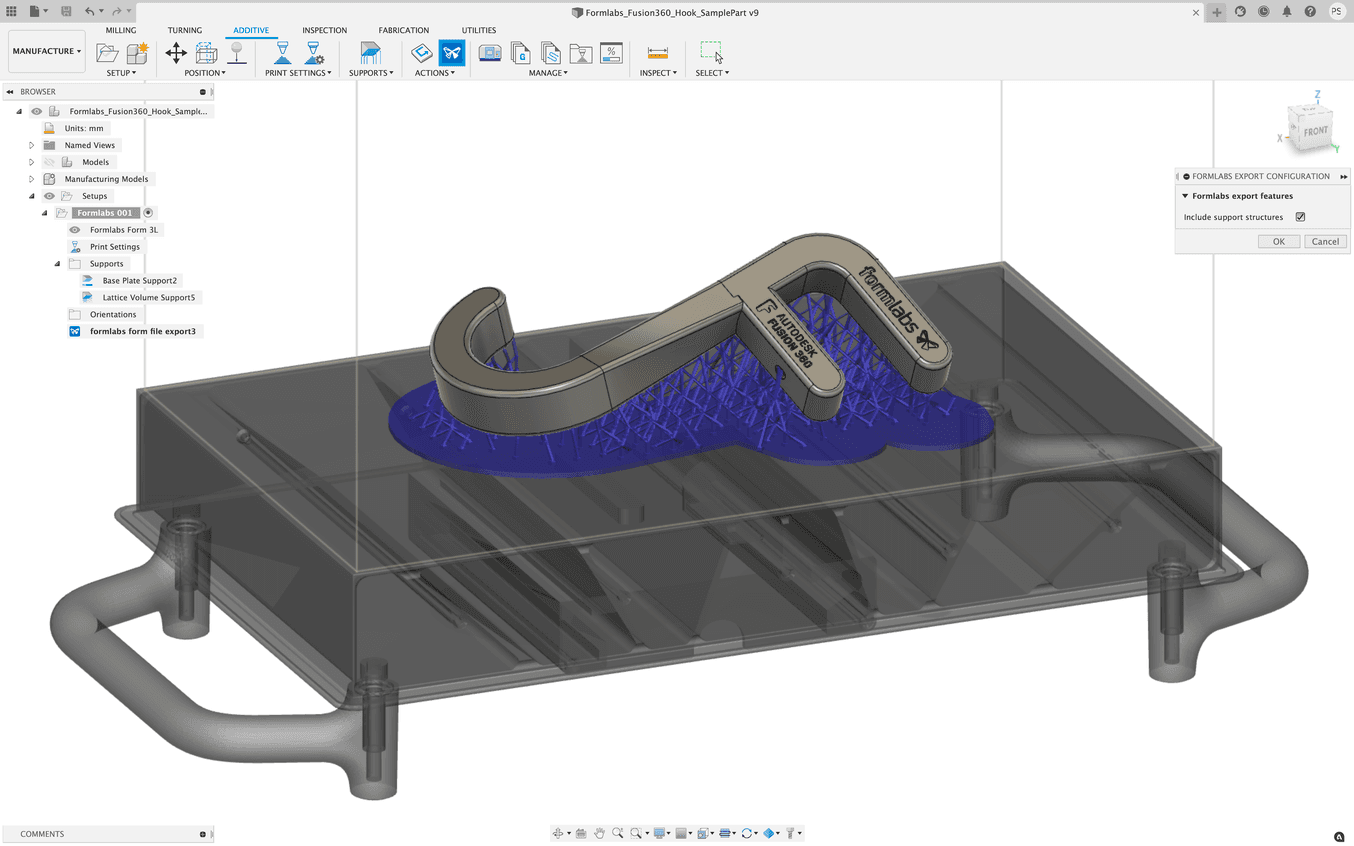

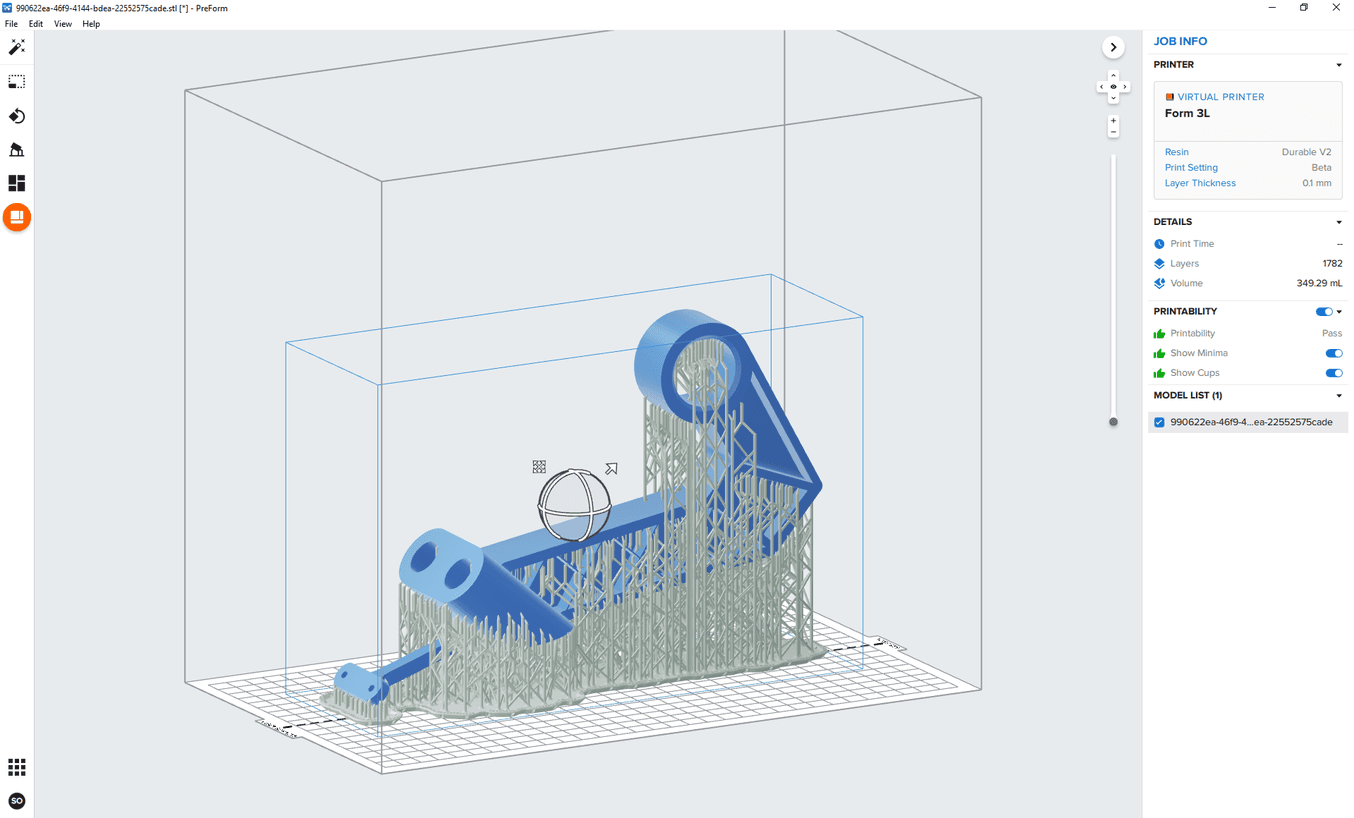

Formlabs and Autodesk have teamed upwardly to streamline your digital workflow with introducing new functionality in Fusion 360 for 3D printing your designs with SLA technology from Formlabs. Our Grade ii, Form iii, Course 3B and Form 3L printers are the first SLA machines to exist included in the Automobile library for Fusion 360. This new workflow combines the all-time of Autodesk'southward versatile CAD package with professional 3D printing results. We're excited to bring this new functionality to Formlabs users, who can now iterate on new ideas in only a few steps.

The software integration includes a brand new graphic interface where users tin can visualize how parts will fit into the Class 2, 3, 3B and 3L build volumes natively in Fusion 360. Private designers tin can orient their parts, adjust them within the build platform and automatically generate back up structures parametrically all within the manufacturing workspace of Fusion 360. If they need to make a design change, their print training operations update automatically. Teams can besides streamline file management by exporting their build platform as a ".class" file from Fusion 360 and open them in PreForm. Shortly additive manufacturing setups created in Fusion 360 will be sent directly PreForm besides. This new integration eliminates the demand to save individual parts as ".stl" files and importing them to PreForm manually, giving designers and manufacturers more reliable version control.

The form feature, denoted past a purple cube, allows the sculpting of complex organic shapes. It opens a new workspace that has a wide array of features for sculpting circuitous shapes. This feature is platonic for creating organic and artistic models for 3D printing.

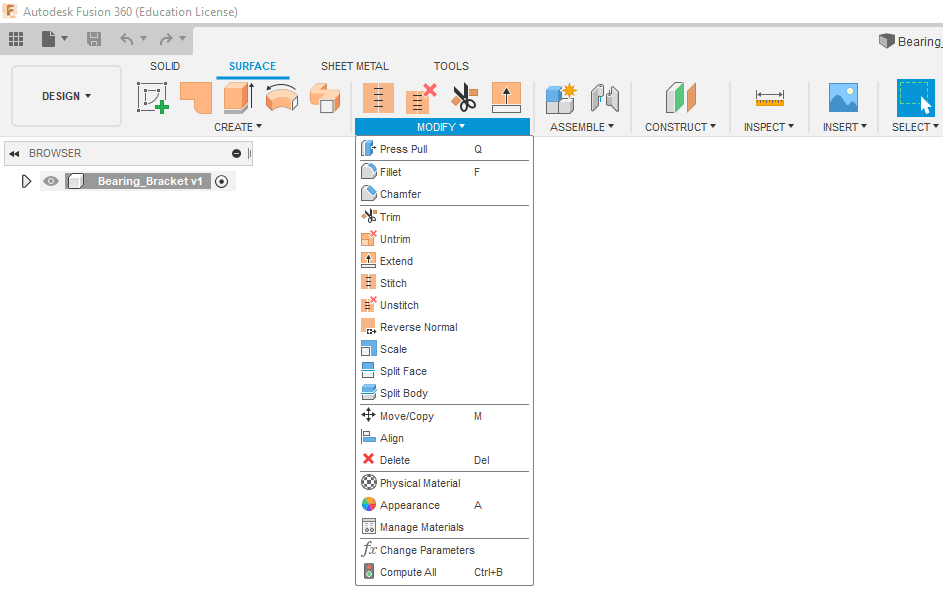

The surface tools allow the user to repair models for 3D printing. Surfaces tin can be stitched closed, extruded, pulled, and pushed to reshape the role. The surfacing tools too help create a watertight model that has no openings in the beat.

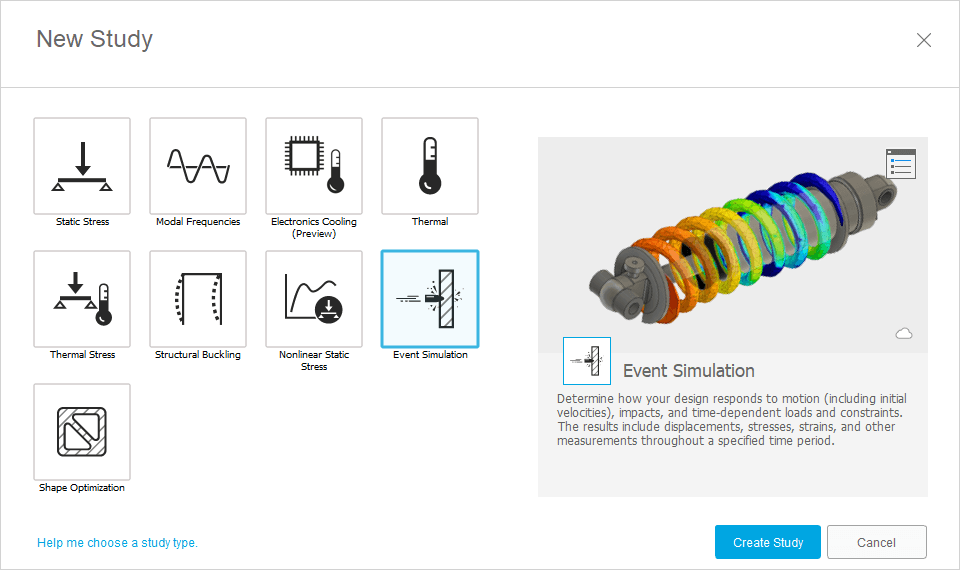

This feature is useful for simulating how your 3D impress will behave under time dependant loads and velocities. For case, snap fit joints tin can be modeled to show what loads are experienced by the clip every bit it is forced airtight, providing a practiced idea of where the weak points are so that the blueprint can exist optimized.

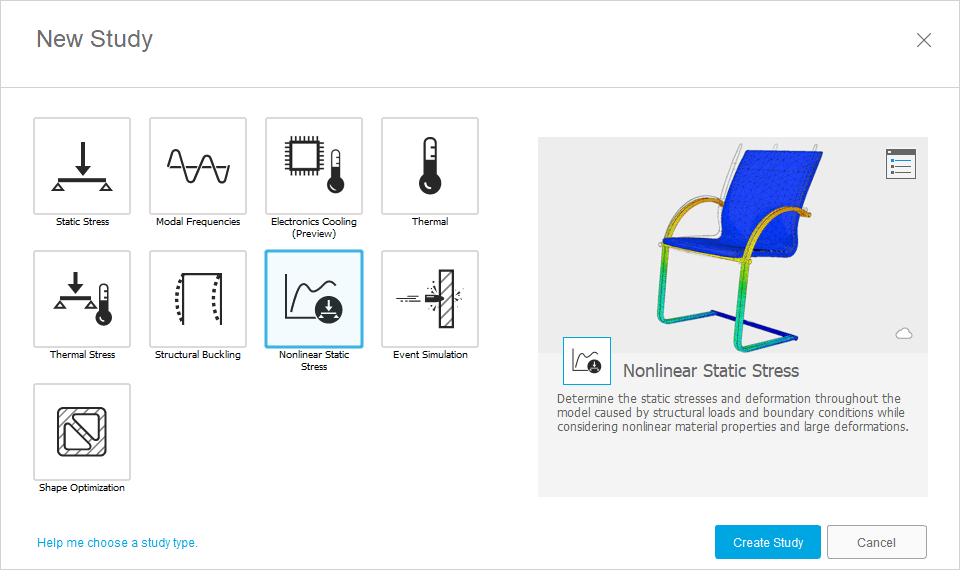

Some 3D printing technologies similar fused deposition modeling (FDM) create parts with non-linear material backdrop that tin simply exist simulated if the FEA parcel has a non-linear study blazon. Fusion 360 features a very capable non-linear study type that tin accurately predict the stress on a component provided the correct material data is loaded in.

Find out more nigh isotropy in 3D press.

Designing for 3D printing is non an overly complex chore, however, there are a few general guidelines to ensure a perfect print every time.

Starting time, consider the 3D press technology that will be used to impress the part(s). This will determine the type of pattern constraints, the levels of accuracy achievable, and support construction requirements

Learn more than about the three well-nigh established technologies for 3D printing plastics today—stereolithography (SLA), fused degradation modeling (FDM), and selective laser sintering (SLS)—in our comprehensive guide.

Wall thickness is critical because parts with too thin walls will exist brittle and might break during 3D press or in mail service-processing. The minimum recommended wall thicknesses vary by printing technology.

Download the Formlabs design guide for stereolithography 3D printers.

Overhangs are easy to print on SLS 3D printers, as the cloth is supported by the unfused powder. Other technologies similar SLA or FDM might crave support structures for overhanging features.

Depending on the technology, press large solid or apartment components can result in warping due to the heat build up in the role. Add pattern features like ribs to make the design structurally stronger and help minimize warping.

Read our guide for ten insights to assistance yous optimize your 3D printing rapid prototyping workflow to be as cost and time efficient as possible.

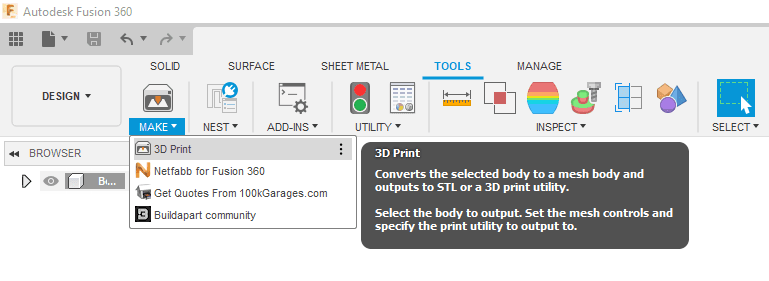

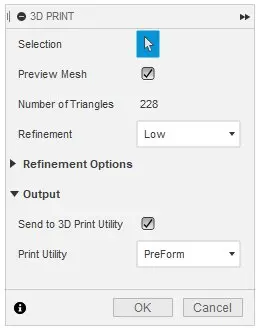

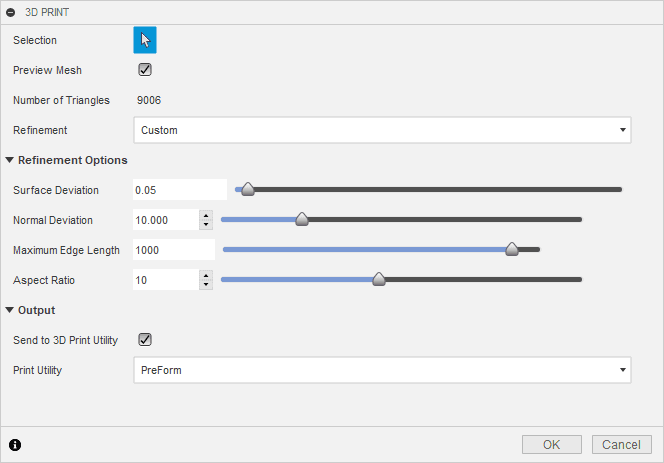

Clicking the Make icon in the Pattern workspace opens the 3D impress menu to make a number of modifications to optimize the model for printing and then ship the model to a 3D print utility.

The menu is broken down into a number of options equally listed beneath:

This option allows the user to select the model for 3D press.

This checkbox shows the mesh on the model that is useful if the user wants to see what effect changes in the settings have on the model.

This shows the number of individual triangles that make up the model. A higher refinement volition increase this number.

This option allows y'all to select i of three pre-defined refinement settings: low, medium, and high. This determines the total number of triangles used in the model. In that location is likewise a custom selection which allows the user to farther refine the mesh based on specific parameters:

Fusion 360 allows you lot to send the model to a range of 3D print utilities such as Meshmixer or Formlabs PreForm for 3D printing.

Use PreForm software to set parts for 3D printing on Formlabs SLA 3D printers.

If the "Transport to 3D print Utility" is not selected Fusion volition export the model as an STL file according to the refinement options selected. This STL file tin can then be loaded into any 3D printer slicer software.

Fusion 360 is a versatile CAD package with an array of features that makes it easy to connect digital workflows and movement from design to manufacturing.

Looking for the right tool to plough your blueprint into reality? 3D printers empower engineers and product designers to rapidly prototype in-firm, saving fourth dimension and costs at every stage of product evolution.

Larn more about 3D printing and come across the quality firsthand by requesting a complimentary sample part printed on the Formlabs SLA 3D printer.

Larn More Virtually 3D Press

harringtoncheyetch.blogspot.com

Source: https://formlabs.com/blog/fusion-360-tutorial-basics-and-tips-for-3d-printing/

0 Response to "dayton form savers 3d drawing"

Enviar um comentário